Every winter season, starting from October to January, air pollution and smog dawn on Central Punjab. Cold temperature and loss of wind velocity play a role in accentuating the intensity of the problem. Burning of rice stubble is one of the major factors, although, all of the problems cannot be ascribed to it.

It has been estimated that rice stubble burning has a 30% share in the total problem of the smog season. Other factors are vehicular traffic, industrial pollution, construction activities and others.

All crops and crop waste burning have been banned in Punjab. There is Section 144 against it. Violators can be fined and even arrested. However, the problem has a large dimension. It cannot be solved through laws and policing alone. There has to be an affordable solution to the problem.

In order to sow the next crop, farmers have to clean the farm land and remove the straw and stubble as quickly as possible. Many kinds of machines have been introduced, which have been employed by big farmers. There have been subsidies for hiring machines and their services as well. Some effect should have been there of these measures, but the problem persists.

There are some smaller but interesting solutions as well. A Harvard/MIT study proposed that only if farmers start burning the stubble two hours earlier, there may be a reduction of 14% in air pollution, saving 10,000 deaths annually in Indian Punjab. They have discovered that Basmati causes much less pollution in stubble burning.

Farmers argue that dew drops on rice stubble make the field too wet for tilling. Burning straw is a low cost and fast solution. It also helps in controlling weeds economizing on the expenditure required on herbs and pesticides.

They argue that machines are too expensive and unaffordable. However, if the stubble is sellable at a price higher than the cost applied in cutting and collecting it, farmers should be agreeable and inclined. Punitive laws may then be effective as well in the face of a viable option.

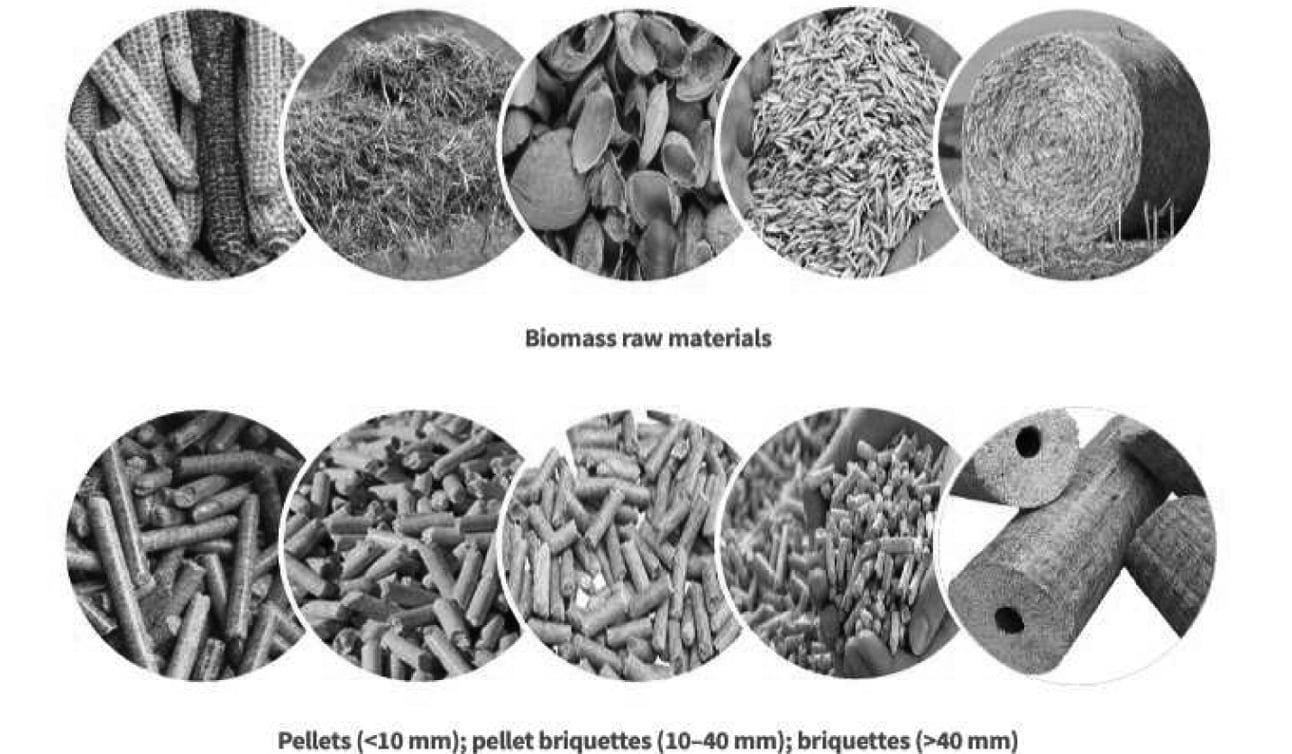

Rice stubble has a mass and energy. It is not useless. It should be made a commodity—a sellable commodity. It can be employed in a number of uses in industries, specifically, in producing energy. And there has to be a use and customer for that energy. There are three market areas; 1. Biogas and ethanol production; 2.Bio-pellets for house-holds, brick-kilns and other industrial furnaces; 3.General market in larger areas.

There are more than 10,000 brick kilns in Punjab, which burn coal. New technology has been introduced in reducing coal consumption. Bio-mass pallets can be employed to replace 20% of the coal consumption, creating a ready market.

There is a ready example in India where legislation has been introduced in this respect. There may be some initial problems in introducing and facilitating a chain of SMEs for producing and supplying bio-pellets. But there is a ready market in brick kilns.

Also, biomass stoves have been introduced that require pellets. Credit and subsidies to promote these stoves will not only help partly solve the air pollution problem by replacing stubble burning in the field. 8.5 million tonnes of rice residue is produced annually. It is a lot of useful material. Coal consumption in brick kilns stands around 3.5 million tons.

However, rice residues CV should be only 40% of that of coal. It appears that brick kilns can consume a significant portion of the rice residue.

The main problem with rice stubble burning is that it is generated and has to be disposed of in a small window of time concentrating air pollution and smog. Its burning in industries over a wider area and in a much larger time slot will reduce the air pollution impact.

However, in case of biogas, it is a highly safe and pollution-less approach. Rice stubble is converted into residue, pretreated and then subject to bacterial digestion in airless large vessels, almost as large as that of big oil storage tanks.

Biogas can be burnt raw or can be cleaned. Raw biogas contains 45-50% CO2 and some H2S, which is removed to produce almost pure Bio-methane. Bio-methane’s main usage is as Bio-CNG. It can replace CNG and let its equivalent be used in other industrial, commercial or residential sector. Raw biogas can promote rural industrialization promoting many kinds of industries.

Another use for rice residue is in the production of bio-ethanol, i.e., ethanol made from bio-resources like rice residue. In Pakistan, ethanol is made by sugar industry and is exported. In other countries, ethanol is mixed with petrol to make 5E (5% mix of ethanol in petrol) and 10E (10% ethanol in petrol).

Bio-ethanol can be exported as ethanol is being exported, earning much-needed foreign exchange. India is utilizing rice residue for both—biogas and bio-ethanol. A plant has been built in India, which will consume 500 tons of paddy straw per day in order to produce 100,000 liter of bio-ethanol per day. Similarly, another plant has been built to produce 100 tons per day of biogas out of 300 tonnes of paddy stubble. Several such plants are in the offing.

Rice stubbles converted into bales can be marketed over a larger market area. Provincial governments can facilitate storage and logistics, if at all it is required. Things should work on their own in the private sector and the markets. Steel furnaces and boilers can also use this. We have mentioned earlier of the prospects of rural industrialization.

We can conclude that rice stubble, which is currently acting as almost a curse, can be converted into a blessing by the three uses as described in the foregoing. The easiest and fastest solution is its usage in brick kilns.

While India has prescribed 20% mix of rice residue with coal to be used in brick kilns, ICIMOD (international centre for integrated mountain development) is trying to take this percentage to 40%. Similarly, there are many other opportunities and resources which are considered as waste or useless can be converted into useful products and commodity, boosting industrialisation and creating employment.

Copyright Business Recorder, 2023

The writer is former Member Energy, Planning Commission and author of several books on the energy sector

Comments

Comments are closed.